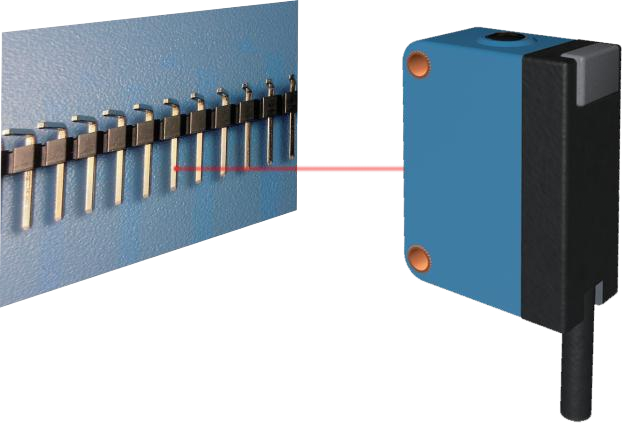

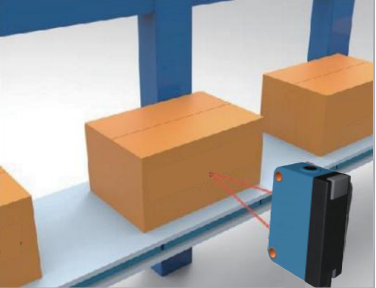

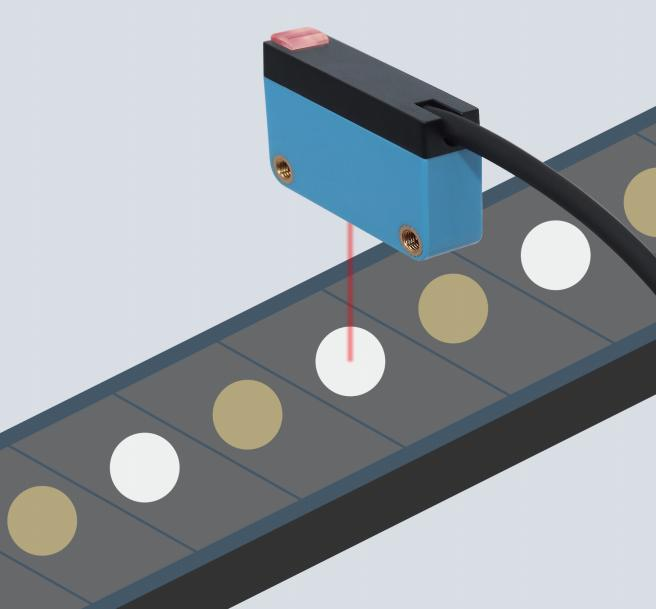

Square photoelectric sensor

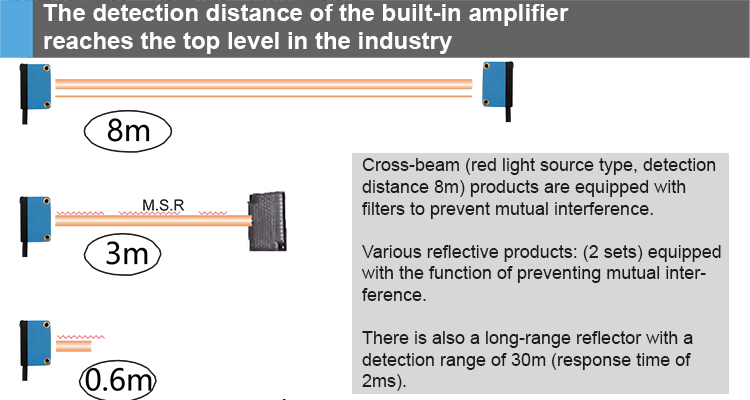

Amplifier built-in type with industry top class

detection distance

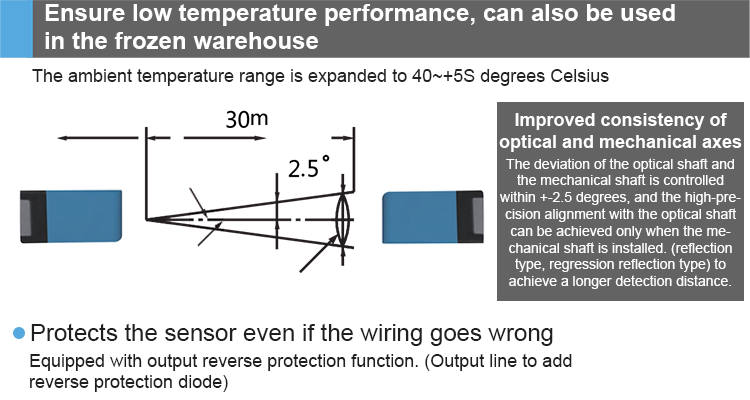

Through-beam type (red light source type, detection distance 8m) product is equipped with a filters to prevent mutual interference. Various reflective products (2 units) are equipped with a function to prevent mutual interference. A long-range through-beam type with a detection distance of 30 meters (response time 2ms) is also available.

Guaranteed low-temperature performance,

even in refrigerated warehouses

Extended ambient temperature range of -40 to +55 degrees Celsius

Improved consistency between optical axis

and mechanical shafts

The deviation between the optical axis and mechanical axis is controlled within +-2.5 degrees, and only needs to be mounted in conjunction with the mechanical shafts to achieve high-precision alignment with the optical axis. Longer detection distances are realized (through-beam type, regression reflection type)

It protects sensors even if wiring is wrong

Equipped with output reverse connection protection function. (Diodes for Square photoelectric sensor Detection distance reverse connection protection added to output lines)

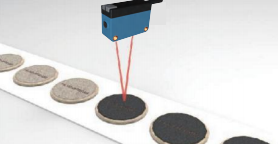

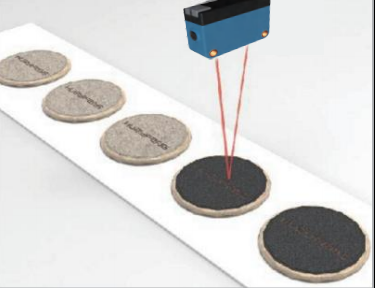

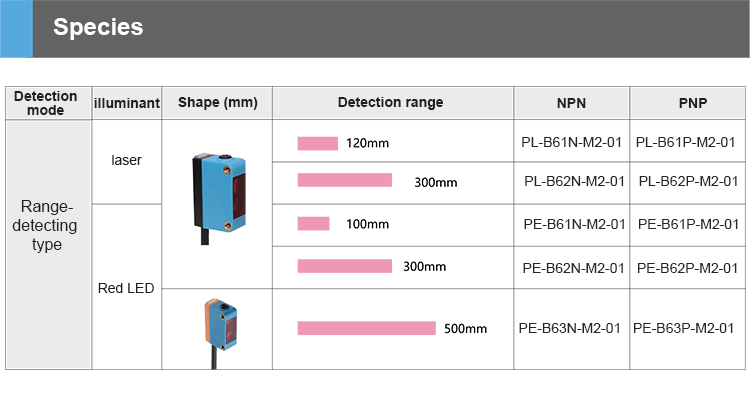

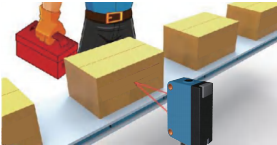

Background suppression photoelectric sensor

Perfect application of BGS function

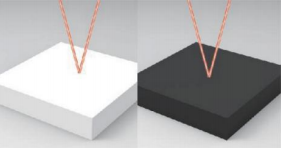

Black and white workpieces can be detected at almost equal distances. There is no need to adjust the detection distance even when changing production on a line where different-colored workpieces are circulating.

Hardly affected by changes in the color of the object to be detected, both black and white can be detected at almost the same distance

When no background

When the workpiece is separated from the background object

Application Examples

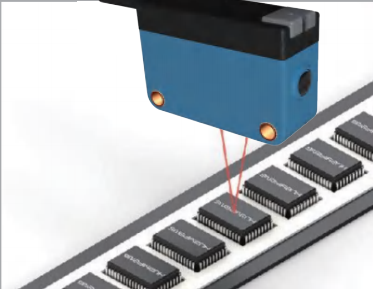

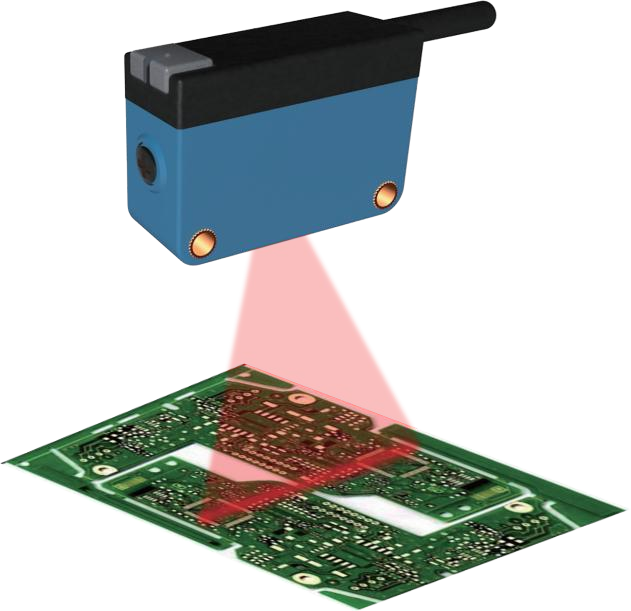

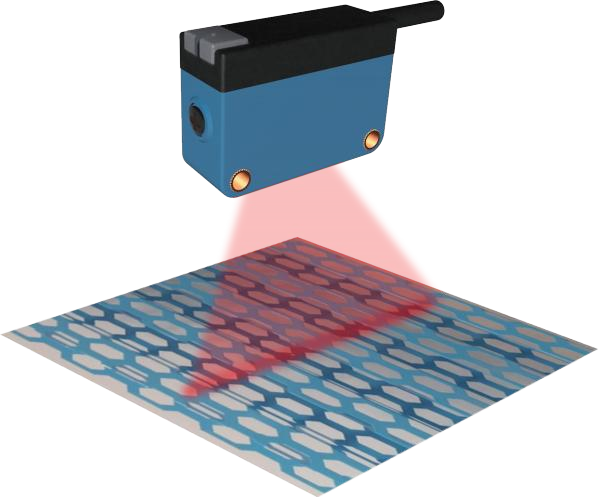

Diffuse reflection bar photoelectric sensor

The strip light design provides a stable detection spot size of 5x30mm.

It has a built-in BG function, making it especially suitable for product inspection of hollow or uneven surfaces.

Intuitive high-brightness red light with high-speed response

The default cable length is 2 meters; customization is supported.

Application scenarios

Detecting irregular hardware

Detection of fine objects in high-speed assembly lines