Fully Certified

Our full range of safety light curtains, safety relays, safety door locks, and magnetic door switches meet the national CNAS unified certification standards, have obtained ISO9100 quality management system certification, and possess CE, PLe, PLd, REACH, EMC, RoHS, FCC and other certifications and test reports.

CPU self-test

The grating uses CPU self-testing. When the grating itself malfunctions (such as: unsynchronized light sources, insufficient light source intensity, error in the projection drive circuit, error in the main control circuit, cable problems, error in the receiver drive circuit, error in the main control circuit, or error in the CPU), the grating can ensure that it does not send erroneous signals to the controlled device, thus ensuring the safety of the light.

Dual independent OSD output

In terms of output, to achieve better safety, dual independent redundant outputs are adopted, which makes automatic fault prevention highly safe and can directly drive safety relays and safety PLCs.

External relay contact adhesive protection (EDM) function

When the output signal of the safety light curtain needs to be connected to the customer’s ordinary relay/contactor equipment, in order to ensure the safety of the entire system, the safety light curtain has an EDM function to monitor the “external relay contact status” to prevent the loss of safety protection functions due to external relay bonding failure.

Superior anti-interference capability

Employing infrared communication and a dedicated optical system, it boasts strong anti-interference capabilities (excellent resistance to electromagnetic signals, strobe lights, welding arc light, and ambient light sources).

More responsive

All grating products in this series have a response time of less than 5ms; overload and short circuit protection: when the safety grating output is overloaded or short-circuited, the grating will enter the protection state, and the grating safety system will be shut down at the same time; self-test: within 2 seconds of power-on, a self-test is performed to ensure that there are no faults.

Power-on delay function

The grating can only be put into normal operation 3 seconds after power-on, which gives the operator and the equipment a buffer time and improves the safety of the equipment and personnel.

Equipped with masking (floating/fixed blanking) function

Customizable automatic shielding and shielding setting functions greatly improve its usability in various field environments.

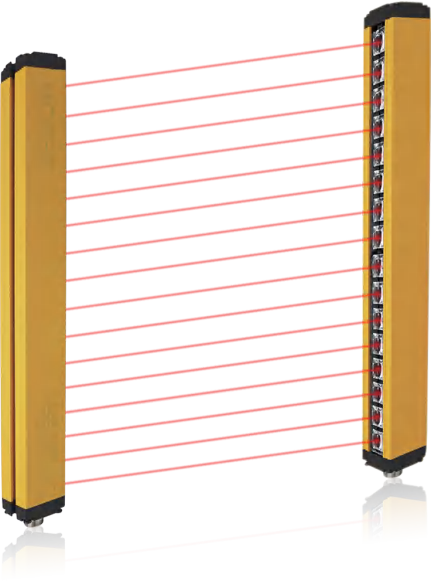

Optical synchronization technology

Unique optical synchronization technology replaces traditional data cable synchronization, avoiding signal interference and eliminating the need for long data cable connections.

Ultra-high detection accuracy

The standard product offers a hardware precision of 2mm and a software cross-algorithm precision of 1mm, meeting the high-end requirements of small spacing, long distance, high precision, and long size of safety gratings.

Equipped with a wide range of detection heights

Detection height range: 60mm~4000mm

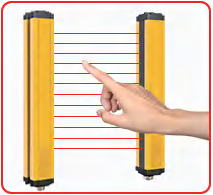

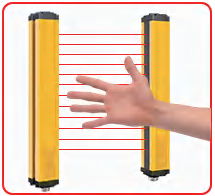

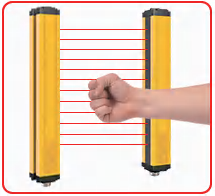

Multiple detection types

Based on the size of the smallest object to be detected, there are three common types.

The minimum detection object for finger detection is Ф15mm.

(Optical axis spacing 10mm)

For palm detection, the smallest detectable object is Ф25mm.

(Optical axis spacing 20mm)

Arm detection uses a minimum inspection size of Ф45mm.

(Optical axis spacing 40mm)

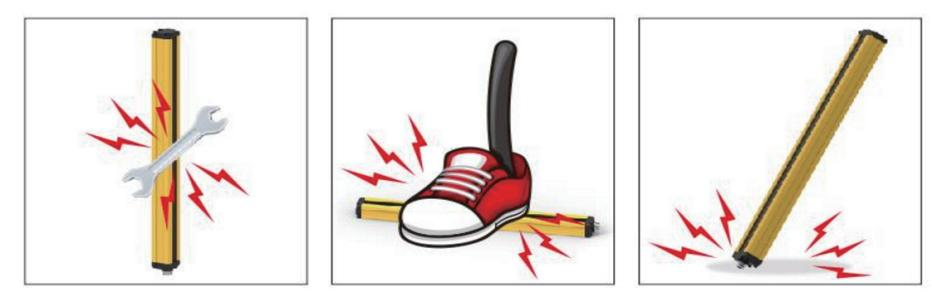

Impact resistant, thick-walled, robust outer shell

The product has a sturdy metal shell, which reliably protects it from various impacts such as workpiece collisions and being stepped on.

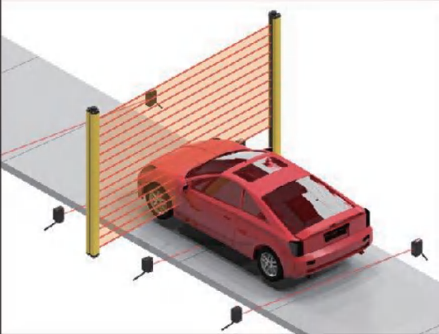

Application scenarios

Production line motion protection testing

Automated operation protection detection