Industrial Automation Equipment with Safety Light Curtain: Ensuring Operational Safety

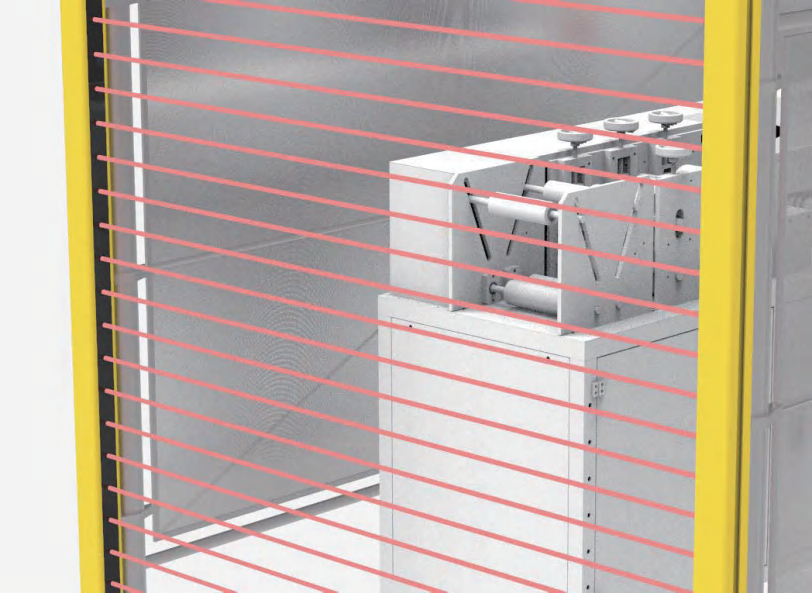

Customized special-shaped safety grating

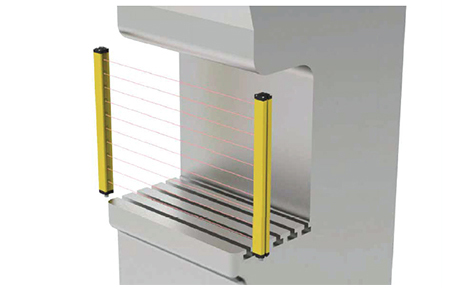

Safety light curtains are photoelectric safety protection devices that emit multiple infrared beams at the transmitter end, which are then received at the receiver end to form a light curtain barrier. When a person or object intrudes into the protection zone defined by the light curtain, its photoelectric detection system responds quickly, triggering the device’s safety control circuit, causing the automated equipment to shut down or enter a safe state, thereby preventing mechanical injuries. These devices are widely used in industrial scenarios such as automated production lines and stamping equipment, and are key components for regional safety monitoring and interlocking control in industrial safety protection.

What is a Safety Light Curtain?

A safety light curtain, also known as a safety gratingin some regions, is a photoelectric safety protection device. It consists of an emitter and a receiver. The emitter sends out a series of infrared light beams, and the receiver picks them up. Together, they form an invisible protective screen. When an object or a person intrudes into this screen, the light curtain detects the interruption and sends a signal to the connected equipment, causing it to stop operating immediately. This swift response is crucial in preventing accidents in industrial settings.

The Synergy with Industrial Automation Equipment

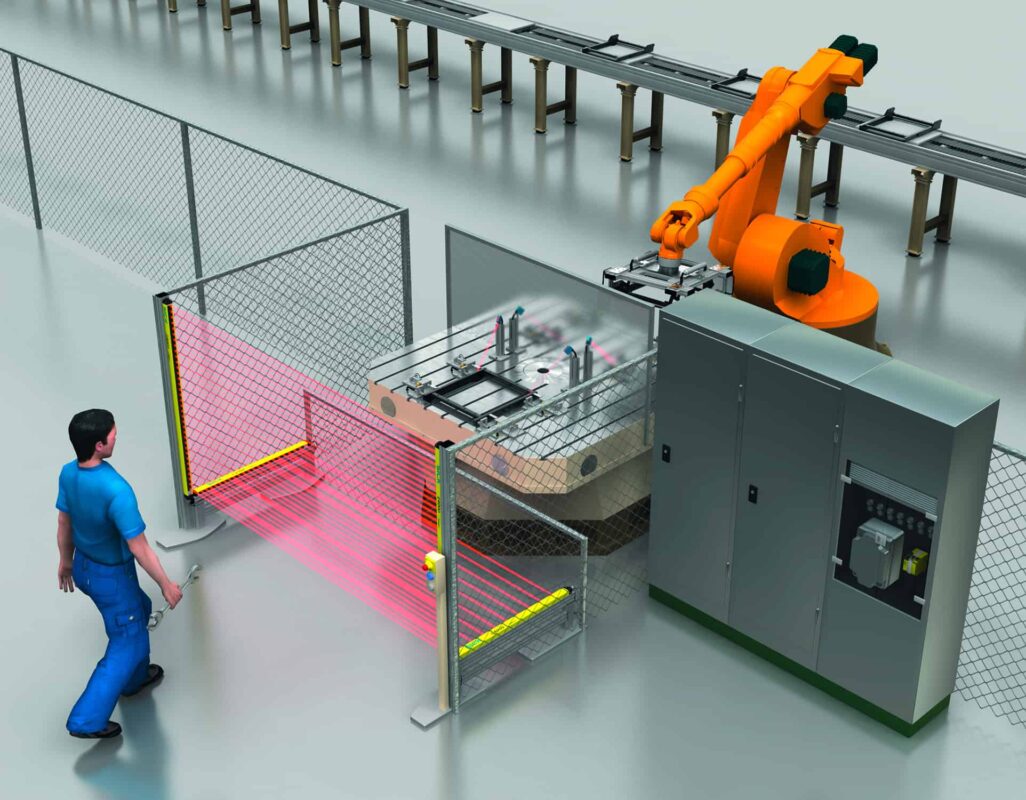

Industrial automation equipment is designed to perform repetitive and often complex tasks with high efficiency. However, the very nature of automated machinery, with moving parts and rapid operations, poses risks to human operators who might need to interact with the equipment for maintenance, setup, or troubleshooting.

This is where the integration of safety light curtains comes into play. By installing safety light curtains around the hazardous areas of automation equipment, a protective boundary is created. For example, on an automated assembly line with robotic arms that move at high speeds, a safety light curtain can be placed at the entrance to the robotic work zone. If a worker accidentally steps into this zone while the robots are active, the light curtain detects the intrusion, and the entire assembly line shuts down safely, preventing any potential collision or injury.

Key Benefits of Safety Light Curtain – Equipped Automation Equipment

Enhanced Worker Safety

The most obvious benefit is the significant reduction in the risk of workplace injuries. Workers can operate near automated equipment with greater peace of mind, knowing that the safety light curtain acts as a vigilant guardian.

Minimized Downtime

While safety is the primary concern, safety light curtains also contribute to minimizing unnecessary downtime. Unlike some older safety systems that might require manual resetting after a false trigger, modern safety light curtains are highly accurate. They reduce the chances of false alarms, ensuring that the equipment only stops when there is a genuine safety threat. This means less disruption to production schedules.

Real – World Applications

Safety light curtain – equipped automation equipment finds applications in a wide range of industries:

- Safety light curtain – equipped automation equipment finds applications in a wide range of industries:

- Automotive Manufacturing: In plants where cars are assembled, robots handle tasks like welding and painting. Safety light curtains protect workers who need to load parts or inspect the robots’ work.

- Food and Beverage Processing: Automated packaging lines use safety light curtains to ensure that workers are not at risk when adjusting packaging machines or clearing jams.

- Pharmaceutical Production: In sterile environments where medications are manufactured, safety light curtains allow for safe interaction with automated filling and labeling machines.